How collaborative robot companies help the pharma industry?

Pharma Industry And Its Challenges

The pharma industry is increasingly a very complicated business. It is one kind of production that requires the utmost accuracy and efficiency in core manufacturing and packaging. Moreover, they have the challenges to adhere to rules and regulations put forth by the government and regulatory agencies. Most of the production happens in the lab that consists of biological and chemical processes. Research and development are part and parcel of the pharma industry. There is mounting pressure to discover new drugs that can tackle new-age diseases. Pharma needs to come with innovative technology to stay compliant and competitive.

Packaging drugs is another challenging task. With new drugs being invented and moved to retail, packaging needs to evolve and accommodate them. Packaging depends on the product range, and there is a set standard to follow when you deal with medicines and other drugs. Medicines are sensitive products. The materials used for making the drug, the size of the drug and quantity will affect packaging. The risk of contamination is another factor to be considered while manufacturing and packaging drugs.

It is tough to find resources to do mundane tasks required off the manufacturing and packaging phase. The pharma industry needs to maintain quality control and showcase precision, high reliability, and consistency to remain competitive in this space. Research and development need to develop improve efficiency in drug production. It is highly recommended that the pharma industry and technology go hand in hand to remove most of these challenges to entail better creation with improved efficiency.

Collaborative Robots In Pharma Industry

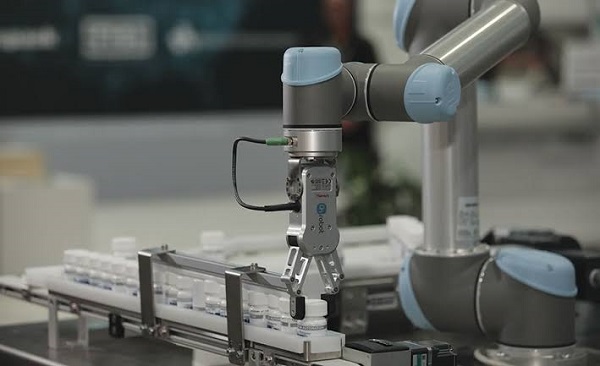

Collaborative robots, or Cobots, are machines designed to work along with the human workforce with less intervention. Most industries embrace automation as it improves productivity, efficiency, and quality. Robotics is one step ahead in the automation segment. Pharma industries require technology advancement to maintain set standards needed to research, produce, and package drugs. Cobots are programmed to perform repetitive tasks, and it can be completed with less error. Compared to a human, cobots are ideal for keeping away contamination by maintaining a sterile environment.

Cobots can be used efficiently in large and small scale labs and used to do a variety of tasks. Automation using robotic technology has gained prominence in the pharma industry compared to other sectors. Both in production and packaging, robots are used extensively. When compared to human resources, work done by robots have fewer errors and have a higher production rate. Though it is highly cost-competitive in the initial stages, the return on investment is quicker. A medication error is a big issue in hospitals as doctors and nurses struggle with similar-looking pills. Intelligent packaging can avoid such mistakes. Pharmaceutical companies are embracing technology at a rapid pace. New trends in business operations have paved the way for new developments.

Cobots And Its Benefits In Pharma

Cobots are replacing human labor and will soon wipe away jobs that tend to involve manual tasks. Invasion of technology has helped increase high tech and innovative careers that are more rewarding and engaging. Cobots, along with humans, can create a controlled work environment that can boost productivity. Collaborative robots can work with hazardous chemicals and biological experiments that are relatively harmful to humans.

Cobots can be programmed to produce high-quality medicines. The use of robots has made pharma industries optimize the process to meet quality control and strict regulatory requirements. It ensures that there are high yield and low wastage. Pick and place operations can be done so precisely. By implementing 3D vision calibration to measure objects, robots are made capable of performing tray stacking by loading and unloading tray parts.

Laboratory processes is another section in the pharma industry that requires the assistance of robots. Robots can accurately move chemical and biological samples to synthesize or test the existing molecules. The robot can help perform repetitive actions and be precise, which is required for lab tests. Challenging tasks like detecting metal contaminants, foreign objects, and underfill, overfill can be efficiently performed using robots. Mass production can be done efficiently, removing all kinds of low-quality products on the assembly line. Throughout the lifecycle of the drug, robots help bring about enhanced production with high quality that is compliant with standards. Click Here – To know more about the applications of collaborative robots.